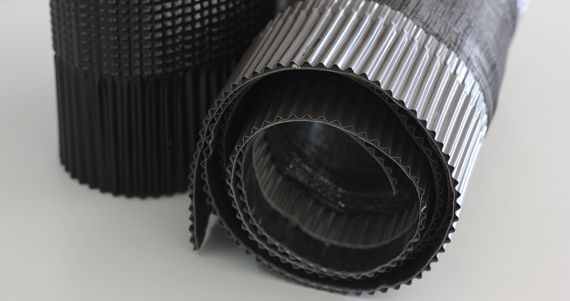

i nsulax® RF is the designation of ALUCOAT for the lacquered foil intended to be used for the production of insulation structures for building (roofs, chimneys, among others). insulax® RF our product to be used in the production of insulation for roof ridges and edges after combination, provides an excellent barrier for humidity, gas and U.V. light. It can be supplied in a wide range of colours and different qualities of lacquer.

nsulax® RF is the designation of ALUCOAT for the lacquered foil intended to be used for the production of insulation structures for building (roofs, chimneys, among others). insulax® RF our product to be used in the production of insulation for roof ridges and edges after combination, provides an excellent barrier for humidity, gas and U.V. light. It can be supplied in a wide range of colours and different qualities of lacquer.

ALUCOAT supplies its product insulax® RF in reels of wide until 1.600 mm, with core of steel or carton up to 500 mm and maximum weight of 6 tonnes.

insulax® RF is specially suitable for roofing isolation, it keeps perfect air conditioning and protect against external agents.

Covering properties:

| PROPERTY | METHOD | insulax® RF |

|---|---|---|

| Top layer | Coloured lacquer, polyester, superpolyester | |

| Aluminium | 8011/1200/8079 O | |

| Bottom layer | Coloured lacquer, polyester, superpolyester | |

| Standard colours | Wide range of colours RAL | |

| Adherence | ASTM D-3359 | No delamination |

| Bending | ECCA 7 (0 ≤ T BEND ≤ 1) | O.K. |

| Curing | Resistance to MEK | > 50 d.f. |

| Heat Resistance | 240ºC/2 min. | O.K. |

| Corrosion Resistance (Neutral Salt Spray) | ASTM B117 (NaCl 5%/35ºC) | >500 h (According to specification > 1000 h) |

| U.V. Resistance | ASTM G154 (500 h.;UV-313 4h. 60ºC / Condensation 4h. 40ºC) | O.K. |

Recommended alloys:

EN AW 8011A, EN AW 8079, EN AW 1200, EN AW 1050 (according to European Standards (EN 573-3))

Customer can specify its needs in order to choose the best thickness, alloy and temper of the metal.

| Analytical cookies | They are used to quantify the number of users and examine their navigation, thus being able to measure and statistically analyze the use made of the website, in order to improve the contents and the service through it. They can be first-party or third-party cookies. If they are not accepted, the indicated analysis will simply not be carried out. | |

| Personalization or identification cookies | They allow us to offer a more personalized experience of the contents of this website (e.g. language), show relevant contents and send the messages or alerts requested by you. If they are not accepted, the navigation will be carried out, but without taking into account these preferences. | |

| Social media cookies | They are used to be in contact with a social network, share content, send and disseminate comments. If they are not accepted, it will not be possible to connect to social networks from this website. | |

| Advertising cookies | They are used to manage and optimize the advertising you will receive as a user, such as, for example, which ads are most relevant or the frequency with which they are shown. They can be first-party or third-party cookies. If they are not accepted, advertising will continue to be displayed, but will not be personalized. |