Dez 29, 2021

Dez 29, 2021

alucoat

Dez 29, 2021

alucoat

Dez 29, 2021

alucoat

Nov 30, 2021

alucoat

Nov 30, 2021

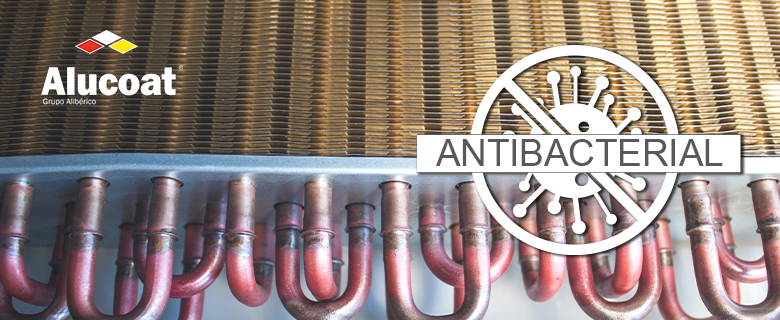

In the R&D department of ALUCOAT, looking to answer our customer’s needs and in our intention to extend the properties of our current products, ALUCOAT has developed the new Airfin 100+.

This new product is designed for the product of finstock for heat exchangers. Thanks to this new development now with antibacterial properties and moreover heat resistance corrosion, this guarantee the no proliferation of bacteria with a 99% of efficacy based according to JIS Z2801-2010/ISO 22196.

Of all the solutions for heat exchangers that ALUCOAT offers, it has the improved version of one of the most popular for its customers, Airfin 100+, moreover it has a higher versatility with new applications thanks to its antibacterial properties.

Thus, Airfin 100+ is the perfect combination with Insulax IP+ that is specially designed for the production of PIR/PUR foam sandwich panels that make the perfect team for areas in which the hygienic conditions are the most important element. Sectors such as sanitary, food or pharmaceutical benefit from this new product as it ensures that the spaces are innocuous and are perfect for keeping the environment hygienic and free of bacteria.

ALUCOAT, specialist in coated aluminium coils from 20 to 500 microns, implicated in your security and health (SDG 3). Protecting you and your environment.

alucoat

Okt 25, 2021

alucoat

Okt 25, 2021

ALUCOAT, is an expert in coating aluminium coils between 20 and 500 microns thick. ALUCOAT supplies materials certified as “safe materials” to a wide range of sectors such as food, pharmacy, insulation, construction, among others and in its daily activity contributes to global sustainability, recycling all the aluminium waste generated when coating.

Aluminium is one of the materials presents in the earth’s layer that is 100% recyclable, it can be recycled infinitely many times and it can be re-used without losing its properties with a 95% of recovery rate. As a curious fact, the 75% of all the aluminium produced in the World since 1950’s it still in use*. Another advantage related with recycling is that it’s avoid the emission of an average of 90 million of CO2 to the atmosphere per year*. Regarding the energy required in its initial production to obtain primary aluminium, giving aluminium a new life means an energy saving of 95%.

For these reasons, ALUCOAT, committed to sustainability and the future, recycles 100% of all the waste generated during its productive process of coating. Moreover, more than 60% of our coated aluminium comes from recycled aluminium, minimizing the extraction of new resources and promoting the circular economy.

ALUCOAT, helping to reduce carbon footprint and greenhouse gases.

*Data from International Aluminium Institute: recycling.world-aluminium.org

alucoat

Jul 19, 2021

alucoat

Jul 19, 2021

The Aluminium Stewardship Initiative, ASI, is a certification and standard-setting organization that recognizes and promotes responsible aluminium production, sourcing and stewardship. This global initiative was created to support members of responsible supply chains and is the result of producers, users and stakeholders coming together to create an agreement on “responsible aluminium”. This enables the entire aluminium industry to demonstrate accountability and provide independent, credible and verifiable evidence of its environmental, social and management performance.

Certification according to ASI Performance Standard Certification is based on 11 principles and 62 criteria including production management, business integrity, transparency, materials stewardship, environmental care, CO2 emissions or labor rights.

ALUCOAT, specialist in coated aluminium coils between 20 and 500 microns, has joined this initiative as a member since June, being this the beginning of the path towards obtaining the certification ASI Performance Standard Certification in the next two years to demonstrate the responsible aluminium production, supply and management.

ALUCOAT, committed to SDGs: industry, innovation and infrastructure (SDG 9), responsible production and consumption (SDG 12) and climate action (SDG 13).

alucoat

Jun 17, 2021

alucoat

Jun 17, 2021

insulax® Kitchen is the coated aluminum especially designed for the production of plinths, boards and kitchen panels. This product, developed by ALUCOAT is resistant to humidity, gas and cleaning products. Moreover, it is resistant to U.V. rays, therefore it does not lose its color despite wear and tear caused by sun or chemical agents and the surface is resistant to cold liquids as specified in the norm EN-12720. Thus, ALUCOAT take care of your health, wellbeing and that of yours (SDG 3).

insulax® Kitchen is a versatile product that can be produced in thickness between 60 and 100 microns and has multitude of finishes available: smooth, brushed, gloss, semi-gloss, matt and a wide variety of colors, therefore, in addition to protecting your kitchen and keeping it in perfect condition, it is the perfect ally for your decoration.

The back finish, the one on the back, can be laminated in a wide range of supports such as: boards DM, melamine, PVC, ABS, CAB, among others. This is the reason why insulax® Kitchen has a large variety of applications.

ALUCOAT offers once again a new, modern, elegant, technical and specific solution according to the needs of each customer

alucoat

Mai 27, 2021

alucoat

Mai 27, 2021

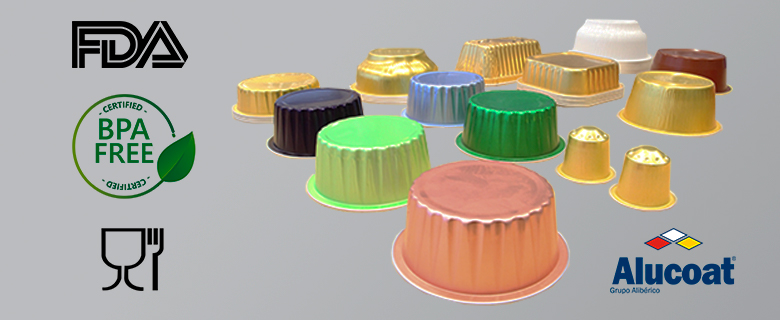

ALUCOAT, leader in coating aluminium coils between 20 and 500 microns, has as one of its main objectives to ensure the maximum safety of all its products, especially those intended for direct contact with food.

A flan container, a yogurt lid, a protective lid of a bottle of wine or coffee capsule, as just some examples of the products are made with the coated aluminium coils we manufacture in ALUCOAT. The aluminium acts as a barrier to protect the inline content against humidity, odors or other external agents that could alter its composition.

The company regularly performs tests based into the European law related with food security such as Regulation (EC) No. 1935/2004, Regulation (EU) No. 10/2011 or Regulation (EU) No. 1907/2006, all considered the most demanding worldwide. Furthermore, ALUCOAT products also comply the requirements of 21 CFR § 175.300 of the US regulations, FDA.

On the other hand, it is registered in the Spanish Food Sanitary Registry that means it has the authorization to produce the articles designed to be in contact with food. This implies that facilities, the production process, the quality standards, the packaging and labelling of our products, satisfy the regulations.

In this way and thanks to the innovation and development process in which we are immerse, it ensures the coated aluminium that leaves our facilities is versatile, provides quality solutions and, for sure is safety for food contact.

ALUCOAT, safety available to the customer. Health and well-being within the reach of all and for all (SDG 3).

alucoat

Apr 20, 2021

alucoat

Apr 20, 2021

ALUCOAT celebrates 20 years, a long history where effort, commitment, enthusiasm, hope and dedication have resulted in exponential growth since it was acquired in 2001 by ALIBÉRICO.

Located in Linares, Jaen and with 80.000 sq. of facilities, ALUCOAT has been a very important driver for this city both economically, labour and social.

In these 20 years, boosted by the rapid growth of its industrial activity the company has given back the illusion to many people by creating quality employment with permanent jobs. It has also opted for education and the youngest, collaborating with Universities and Professional Training Centres, offering them real opportunities to join the world of work. In addition, it has made great efforts and investments in innovation and development, which has allowed it to develop its own technology, managing to offer unique products of the highest quality.

In these 20 years, ALUCOAT has demonstrated its commitment with people and Linares, a priority objective in which it will continue working to continue being a benchmark company in its sector, coated aluminium coils. Moreover, ALUCOAT assumes it environmental compromise, carried out strict quality controls to reduce consumption and the production of raw material and energy (SDG 7 and 12) and optimize all resources to minimize its impact on the surrounding ecosystem (SDG 13 and 17).

That is why the activity of ALUCOAT is essential and strategic not only for Linares but for Spain, because it contributes to the economic and stable growing.

ALUCOAT always committed to people, the environment and innovation.

alucoat

Mrz 11, 2021

alucoat

Mrz 11, 2021

Alucoat® cs is the product designed for the production of packaging for food industry. Thanks to many years of work, constant development, know-how and innovation, ALUCOAT has been adapting its coated aluminium coil thanks to the most advanced technology and the requirements of a highly demanding market such as food. Its objective is to offer products and services with high quality, achieving the maximum food security for its customers.

As a results of the extensive experience with this product, ALUCOAT has achieved that moreover to complying with the properties of lacquered aluminium such as preservation of food in perfect condition, resistant to heat and corrosion as well as boiling water, ensure the following requirements:

ALUCOAT invests great efforts in research and development to offer its customer an improvement in the mechanical properties of the product, working with special alloys that reduce the thickness of the material and increasing its performance, while keeping the quality standards of the product.

Being able to supply its lacquered aluminium coil in a wide range of colors and customize the final product, Alucoat® cs becomes the star product for food packaging.

ALUCOAT, oriented to customers, focused on the product and always committed to innovation (SDG9).

alucoat

Feb 23, 2021

alucoat

Feb 23, 2021

linfoil® is the ideal solution for the production of lids for dairy products, patés, jams, among others.

Within the linfoil® product range, ALUCOAT launches the new linfoil® 400 +, an improved version of our standard linfoil® 400 which allows compliance with the strictest food regulations such as FDA (Food and Drugs administration, USA) or the European food safety. Thanks to the absence of both BPA (a substance presence in plastics that can contaminate food) and PVC (plastic), both specifications very claimed in food sector. Moreover, thanks to its special composition, it can be heat-sealed to all possible substrates: aluminum, glass and plastic containers.

With ALUCOAT lids and thanks to its barrier protection against light, humidity and flavors loss, as well as the prevention of external contamination, the safety and quality of the product is guaranteed.

ALUCOAT, always working for your health, security and well-being (OSD3)

alucoat

Jan 25, 2021

alucoat

Jan 25, 2021

Linares, January 21st. The president of the Junta de Andalucía, Juan Manuel Moreno Bonilla, visited the Alucoat Conversion factory today in Linares, (Jaen). Belonging to Grupo Aliberico, to show his support for the innovation and growth plans, which has been promoting this industrial and technological company for years, specialized in coating aluminium coils between 20 and 500 microns thick for sectors such as food, pharmacy, conditioning and building.

During his visit, the president of Junta de Andalucia was accompanied by the major of Linares, Raul Caro-Accino and was received by the Director of Alucoat Conversion, Jose Manuel González Plaza and the counsellor of Grupo Aliberico , María González Armero.

Since it was privatized by SEPI in 2001 and acquired by Grupo Aliberico, Alucoat Conversion has invested heavily in innovation and technological transformation, which has allowed it to increase the number of customer and portfolio in critical sectors such as pharmaceuticals and sanitary.

This strategy has led the company to beat the production, turnover and results record in the just ended year.

Currently, Alucoat is immerse in an ambitious plan of digital transformation that will standardize its processes to the 4.0 digital standard. This will affect internally to the company and its relationship with customers and suppliers.

Alucoat maintains intact its commitment to Andalusia and the city of Linares, which is based on the determination to continue growing through investment in new facilities and machinery and the creation of new quality jobs.

Nowadays, the company has a workforce of 70 people, 94% of them with permanent contracts. Furthermore, even being an industrial company, half of the directives positions are held by women.

Alucoat is the unique producer of coated aluminium of in Europe up to 1.650 mm wide, which positions the company as the only one in its sector both nationally and in Europe. Currently, Alucoat exports 50% of its production to more than 46 countries.

| Analyse-Cookies | Sie ermöglichen es, die Anzahl der Benutzer zu quantifizieren und ihre Navigation zu untersuchen. Auf diese Weise können sie die Nutzung der Webseite statistisch messen und analysieren, um den Inhalt und den Dienst durch die Webseite zu verbessern. Sie können eigenen Cookies oder Third-Party Cookies sein. Wenn sie nicht akzeptiert werden, wird die angegebene Analyse einfach nicht durchgeführt. | |

| Personalisierungs- oder Identifikations-Cookies | Sie ermöglichen es, eine personalisierte Erfahrung des Inhalts von dieser Webseite (z. B. Sprache) zu bitten, relevante Inhalte für den Benutzer zu zeigen und Nachtrichten oder Warnungen, die Sie fordern, zu senden. Wenn sie nicht akzeptiert werden, wird die Navigation stattfinden, aber ohne Berücksichtigung von Vorlieben. | |

| Soziale Netzwerke Cookies | Sie ermöglichen es Ihnen, mit Ihrem sozialen Netzwerk in Kontakt zu sein, Inhalte zu teilen, Kommentare zu senden und zu verbreiten. Wenn sie nicht akzeptiert werden, ist es nicht möglich, von dieser Webseite aus eine Verbindung zu sozialen Netzwerken herzustellen. | |

| Werbe-Cookies | Sie ermöglichen die Verwaltung und Optimierung der Werbung, die der Nutzer erhält, beispielsweise welche Anzeigen für ihn am relevantesten sind oder mit welcher Häufigkeit sie ihm gezeigt werden. Sie können eigenen Cookies oder Third-Party Cookies sein. Wenn sie nicht akzeptiert werden, wird die Werbung, die weiterhin angezeigt wird, nicht personalisiert sein. |